|

|

BLADELESS JET

A light weight, simple, cheap, jet engine design.

|

|

|

This is an old drawing of mine, of a jet engine with a cold turbine. The hot jet sucks in a lot of air (looking from behind you'll see a star/flower shape of the air mixer). This air drives the cold turbine. The cold turbine drives the compressor. I forgot to draw the gear between the cold turbine and the compressor. The compressor has a much higher rpm. A cold turbine is less complex and cheaper, relative to a hot turbine.

Although this cold turbine engine to me seems like an improvement on the ordinary hot turbine, a bladeless jet engine without any moving part would of course be even better. The question is how to compress the air to about 1/30, otherwise it will not be fuel efficient & powerful. That is: when working with the explosion principle (air in, compression, "bang", expansion/work, gas out).

|

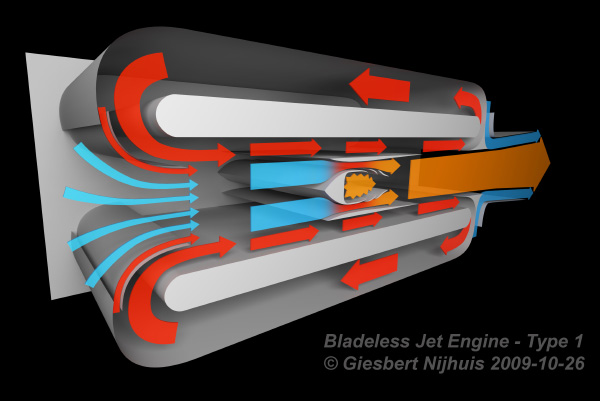

BLADLESS JET - TYPE 1

This bladless design is based on a drawing from when I was a (strange) teenager. I wanted to built a jet engine, but knew that the heat would melt my turbine! So I thought of simple ways to drive air with air instead of blades.

Normal turbine engines are: heavy, complex, and very expensive.

This jet engine is: light, simple, and cheap.

And normal turbine engines are hard to fit in a coanda effect flying disc, while this type fits in just fine.

But, the disadvantages of this design are:

- Compression is low (thus low fuel efficiency & power).

- The fresh intake air is getting warm (also not good for the efficiency).

- The coanda flow is pretty hot. Heat is energy, so that is wasted. It should be cool.

The center of this engine is like a ramjet. But ramjets work most efficiently at air intake speeds around Mach 3. This engine will probably not be able ram the air in with supersonic speeds. So, although a nice design; it has to be improved to be useful.

|

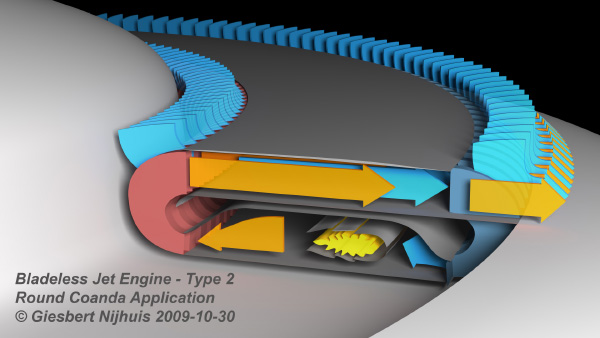

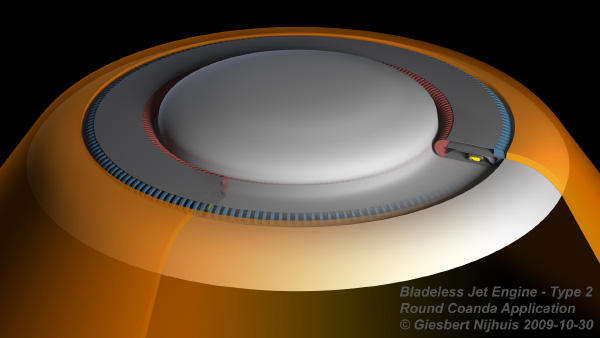

BLADLESS JET - TYPE 2

With this bladless design type 2 I think type 1 can be trashed.

Improvements in type 2:

- The high pressure chamber is much larger, causing a cleaner burn.

- The air drag length from intake to compressor is 3x as long.

- The air drag surface is many times larger, really accelerating the incoming air a lot.

- The exiting air can drag a lot of ambient air mass into the coanda air jet.

- Only 2/3 the thickness.

A straight version of this engine is also possible.

The disadvantages of this design are:

- The drive air's heat will make the temperature of the incoming air rise before it enters the compressor. This is not good for efficiency.

- The coanda flow is pretty hot. Heat is energy, so that is wasted. It should be cool.

So, I am now thinking of a type 3.

|

The ideal aircaft engine

- No moving parts (moving parts make an engine: heavy, complex, unsafe, and expensive)

- Light weight (it's the weight that needs to be lifted and accelerated)

- Reliable (a total loss of engine power easily results in death and destruction)

- Minimum maintenance

- Fuel efficient (slow & clean burning, no waste of heat and sound)

- Minimum polution (chemical waste, heat, sound)

The only thing moving in a jet engine should be the air. Air is able to accelerate other air in its path, so a bladeless jet engine should be possible.

Piston engines are to laugh/cry about. Next to all the parts that move up and down, check out the air: it's accelerated violently without a goal. When the exhaust valves open, pressurized hot air escapes with high speed. What a loss. And also does a lot of heat disappears into the engine, that needs this be cooled. More loss again.

|

Notes

A jet of air in air doesn't want to go straight, and if you don't guide it in the right curve it will curve at its own will, and we call that turbulence. We in aviation often don't want turbulent air, but we accelerate air straight and then complain about turbulence.

A way to get rid of turbulence is to move away from explosion and use implosion instead. Air "wants" to swirl, to vortex.

|

Giesbert Nijhuis

|

|

|